By JOHN KEREZY, eyeoncleveland.com founder

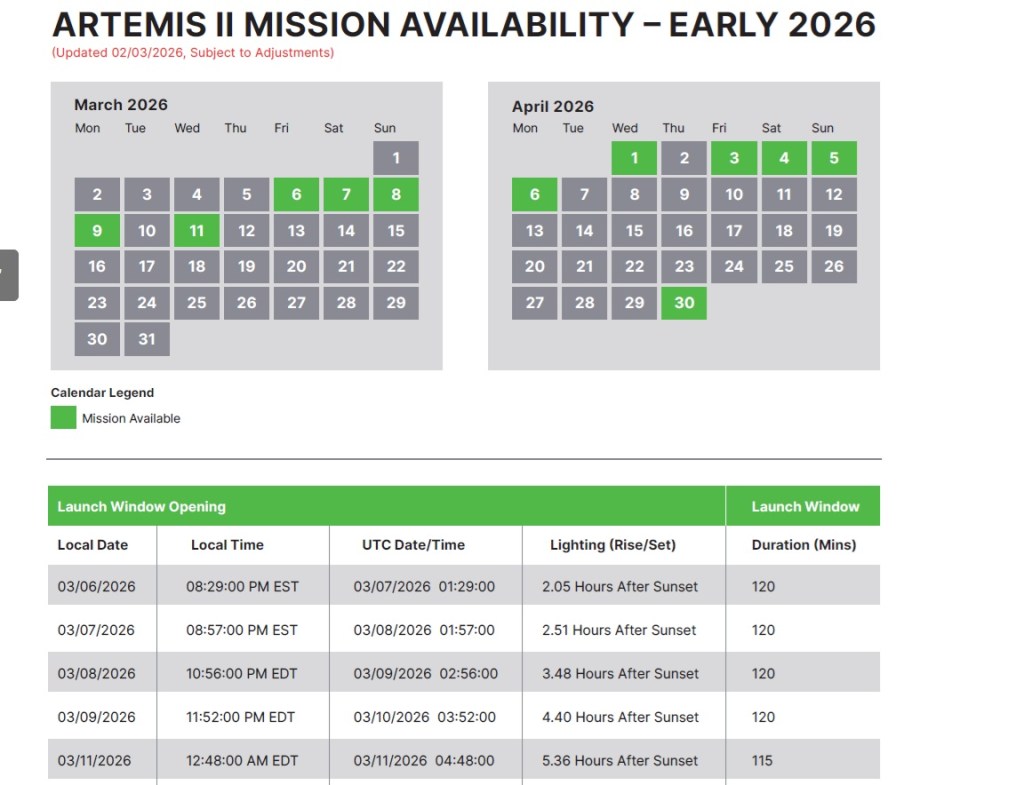

QUICK NOTE: Following NASA Kennedy Space Center’s success yesterday with the Wet Dress Rehearsal for Artemis II, NASA is expected to announce soon that it will aim for the March “launch window” for the moon shot This means launch could happen as soon as Friday, March 6, or two weeks from now. See the launch window below.

CLEVELAND, Feb. 20 — On December 16, 1972, Apollo 17’s three astronauts left lunar orbit to return to the Earth. For more than 53 years, humankind hasn’t returned to the moon or even left low earth orbit. That changes come as soon as March 6, when Artemis II is scheduled to lift off and take four astronauts around the moon.

We’ve broken away from earth’s gravity only nine times on past crewed space mission. Artemis II will be the 10th time, the first with a four-person crew and the first with the Orion spacecraft, designed with travel to the Moon, Mars, and beyond in mind.

And the journey would be impossible without the significant contributions from NASA’s Glenn Research Center in Cleveland.

Begun as a National Advisory Committee for Aeronautics (NACA) research facility in 1941, NASA Glenn was instrumental at its inception in developing superchargers for high altitude bombers and also the laminar flow airfoil for what became the P-51 Mustang fighter plane. The technology coming from (then) Lewis Research helped win World War II.

Today, NASA’s Glenn Research Center is a premier research and testing facility focused on advancing aerospace technology, with specific assignments on air-breathing engines, space propulsion, power systems, and communications. More than 3,000 people work there, conducting and then analyzing their cutting-edge research to support the next generation of commercial aircraft as well as critical manned spacecraft such as Orion and the International Space Station.

Key areas of focus and important accomplishments at NASA Glenn include:

- Aeronautics & Propulsion: As the only NASA center focused on aircraft propulsion, it develops technologies for more fuel-efficient, quieter, and safer commercial flights.

- Space Systems: Key contributions include pioneering liquid hydrogen rocket fuel, electric propulsion (ion thrusters), and power systems for exploration.

- Facilities: Features world-class, unique, and specialized facilities, including large-scale wind tunnels, drop towers for microgravity research, and powerful vacuum chambers (more below).

- Key Programs: Major involvement in the Artemis program (Lunar Gateway), space communication systems (SCaN), and the development of power/propulsion for deep space exploration (more below).

Of those 3,000 employees, more than 80 have been dedicated to research and testing for the entire life span of the Artemis 2 mission. About two dozen NASA Glenn employees will soon pack their bags and laptops and will be flying to either Kennedy Space Center on Merritt Island, Florida, to support the launch, or to Johnson Space Center in Houston for Mission Control and the new Mission Evaluation Room (MER).

Jacqueline Minerd, public affairs officer, adds that NASA Glenn will also have five mission consoles established in Cleveland, manned by subject matter experts from different disciplines (such as propulsion, thermal, etc.) providing assistance at the Orion MER at Johnson space Center during critical points of the mission.

Minerd adds that in Ohio, 79 companies support essential work to help NASA on a variety of missions to the Moon, Mars, and beyond. Ohio has a vibrant space economy, supporting job growth for a highly skilled workforce.

Glenn is also essential to the Ohio economy, fueling industries, supporting job growth, and increasing the demand for a highly skilled workforce. NASA Glenn contributes nearly $2 billion annually to the state’s economy through jobs and business development opportunities, according to a recent study at Cleveland State University, conducted in collaboration with NASA.

Story link: https://greatercle.com/bibvnasaglenn/

Download the PDF of the study here:

POWER, PROPULSION AND MORE

How well will Orion’s solar array deploy and work? How will Orion generate sufficient electrical power to fulfill its 10-day mission? For longer future missions? These are a few of the questions which NASA Glenn engineers and managers have been addressing for years now.

For Apollo, a Service Module housed a propulsion system, electrical power system, hydrogen and oxygen tanks, radiators, and (in Apollo 15-16-17) an instrument bay containing mapping, science experiments, and photography.

For Orion, there’s an important new partner involved in this adventure: the European Space Agency. Eleven different countries are part of the process, designing and manufacturing what’s called the European Service Module or ESM. The powerhouse of the spacecraft, the ESM has 33 engines to provide in-space maneuvering. It has four solar arrays (wings) to produce 11.2 kW of electrical power – the equivalent of two, 3-bedroom homes. About 10 percent of this power goes to the ESM systems, and the other 90 percent support the Orion crew module. The ESM also contains water, nitrogen and oxygen.

At NASA Glenn, engineers and researchers have devoted decades to investigating ways to best provide power and propulsion for both manned and unmanned space vehicles. The Systems Engineering group in Cleveland operates a European Service Module Integration Office, ensuring that everything in the ESM meets or exceeds NASA specifications.

Logan Larson is the European Service Module System and Mission Manager. “The people on this program are amazing,” he says. “Working with and learning from individuals with such diverse expertise – including our European partners – has been invaluable.”

TECH NOTE: The Artemis SLS core engines will shut down eight minutes and four seconds after liftoff. The huge rocket’s two stages separate 12 seconds later. Another 10 minutes after that, or about T-plus 10:30 in the mission, Orion will start deploying its ESM’s solar arrays. That process will take about 12 minutes. Project Apollo relied on fuel cells for power for its mission. Orion operates 100 percent on electrical power, provided by batteries and solar arrays.

LINK: https://www.nasa.gov/humans-in-space/orion-spacecraft/european-service-module/

TESTING: SHAKE, BAKE AND FREEZE

How will Orion do with the vibration and sounds on liftoff? Might the spacecraft be damaged? How will it handle the extreme temperature variation it’ll encounter?

To test full-sized spacecraft and hardware for all of the extreme situations and conditions of launch and space flight, NASA built the Neil Armstrong Test Facility (ATF) in Sandusky. The site itself dates back to the 1950s, and NASA began rocket testing there in 1958.

Today the ATF’s Space Simulation Vacuum Chamber, 120 feet tall and 100 feet in diameter, is the world’s largest and is designed to test equipment both in the vacuum of space and for EMI/EMC, or electromagnetic interference/compatibility. It consists of two chambers: the inner vacuum chamber, constructed of aluminum and meant for high vacuum, and the outer enclosure, constructed of reinforced concrete 6 to 9 feet thick.

“Our Space Simulation Vacuum Chamber has a mix of clients,” says John Zang, Division Chief of the Environment Test Division at NASA’s Glenn Research Center ATF. “(We service) NASA internal programs like Orion and we have commercial partners: SpaceX Blue Origin, and ULA (United Launch Alliance). “We can perform full-scale deployment tests of upper-stage payload fairings, (providing) critical information to their potential stakeholders and partners.”

TECH NOTE: A payload fairing is a cover designed and used to protect a spacecraft payload against dynamic pressures and aerodynamic heating during launch. The fairing must jettison correctly once in space, in order to have its payload (satellite, spacecraft, etc.) function properly.

The Space Simulation Vacuum Chamber also can conduct thermal cycle tests of space hardware. “We utilize recirculating nitrogen gas and can run a test and pinpoint a temperature between negative 255 degrees (F) to 170 degrees (F),” adds Zang. “Unique is most definitely the adjective that best describes many of our capabilities in Sandusky.”

But baking in heat or freezing in cold aren’t the only challenges Artemis and its Orion spacecraft face. Acoustic pressure can have a dramatic impact on space components, especially at launch.

at NASA’s Armstrong Test Facility in Sandusky.

Anyone who’s watched a launch of the Saturn V Apollo rocket, or the Space Shuttle, or Artemis 1 probably noticed the voluminous amount of water NASA’s launch teams pours – more than 400,000 gallons – onto the launch pad at liftoff. The water’s main purpose is to suppress sound pressure, which is happening at very high levels as the rocked lifts of from Pad 39B at Kennedy Space Center.

TECH FACT: Sound pressure level is measured in decibels, or dB. Normal conversations are at about 60 dB. If you’re at an airport outdoors, you’ll hear a jet engine about 120 dB. The Saturn V rocket produced sound pressure at about 200-205 dBs. The Space Shuttle reached a sound pressure level of 180-200 dBs. Sensors at the launch pad measured dB levels of 162-172 at the Artemis I launch in November 2022.

In preparation for Orion, NASA added two new test facilities at the ATF. One of them is the Reverberant Acoustic Test Facility or RATF. It is the world’s most powerful acoustic chamber. “We are testing for acoustics that might adversely impact spacecraft performance,” Zang explains.

Orion’s designers also reverted to a launch abort system similar to Apollo’s. A shroud with three rockets atop covers the entire crew module. In case of an emergency or an abort, the system’s solid rocket motors can accelerate from 0 mph to 500 mph in two seconds, swiftly carrying away Orion from the SLS rocket. NASA wanted an Orion testing requirement for a launch abort scenario, and the ATF team answered the call.

“The launch abort system would activate a high level of acoustic noise on the crew module of Orion,” Zang notes. “We wanted to test that to ensure the crew could withstand that pressure.”

The second new facility is a MVF, or Mechanical Vibration Facility. This is the world’s most powerful, high capacity shaker system, with three axes and six degrees of freedom. “The MVF is unique, a shaker table structure,” Zang explains. “We put many Orion components under MVF stress repeatedly, to make sure they would operate fine in the launch and flight process. We do this, qualification and acceptance testing, for many types of flight hardware.”

The ATF received the Orion 1 spacecraft back to Northeast Ohio after its 1.4-million-mile journey in November-December 2022. “After Lockheed Martin refurbished the spacecraft at Kennedy Space Center, we partnered with them to put it through several different scenarios again, including a lightning test, acoustic cover test, and also an abort sequence test, Zang adds..

NASA Glenn also tested Orion’s forward bay cover, which is removed prior to firing the pyrotechnics for the spacecraft main parachutes near the conclusion of re-entry.

Zang is a Northern Ohio native. He started as a mechanical engineer for ATF (formerly named Plum Brook) contractor in 2006. He became a civil servant in 2010 at Glenn Research Center, then transferred back to ATF as a senior mechanical engineer in 2014. He was then promoted to the Glenn Research Center’s ATF test manager at the SEC in 2018. He was promoted again to SEC Complex Manager in 2021, and became Division Chief of the Space Environments Test Division in 2023.

Zang earned a mechanical engineering degree at the University of Toledo and lives with his spouse and family in the Castalia are. Like Zang, thousands of professionals at NASA Glenn have striven for and are now rooting for a successful Artemis II mission for Orion and its four-astronaut crew of Reid Wiseman, Victor Glover, Christina Koch and Jeremy Hansen.

So when Artemis II lifts off from Florida, its path — before launch — journeyed through Northeast Ohio at NASA Glenn to help ensure a successful mission to the moon and back.

SOME SOURCES USED

FROM NASA

https://www.nasa.gov/the-road-to-the-moon-goes-through-ohio

Wall, Mike “Artemis 1 timeline: What to expect from NASA’s epic moon mission,” August 22, 2022. https://www.space.com/nasa-artemis-1-moon-mission-timeline

Robinson-Smith, Will, “Cold weather delays earliest Artemis 2 launch opportunity”https://spaceflightnow.com/2026/01/30/cold-weather-delays-earliest-artemis-2-launch-opportunity/

Want to see a video of a test of the functionality of Orion’s forward bay cover, which is the last piece that must eject before parachutes deploy? Here it is: https://www.nasa.gov/wp-content/uploads/2024/12/fbc-jettison-sideview-highspeed-shortclip.mp4

You can take a video tour of the Space Environments Complex at NASA’s Neil A. Armstrong Test Facility in Sandusky, Ohio here: https://www3.nasa.gov/specials/sec360/

SPECIAL THANKS TO: Public Affairs staff at NASA’s Glenn Research Center for their assistance with interviews and information for this story.